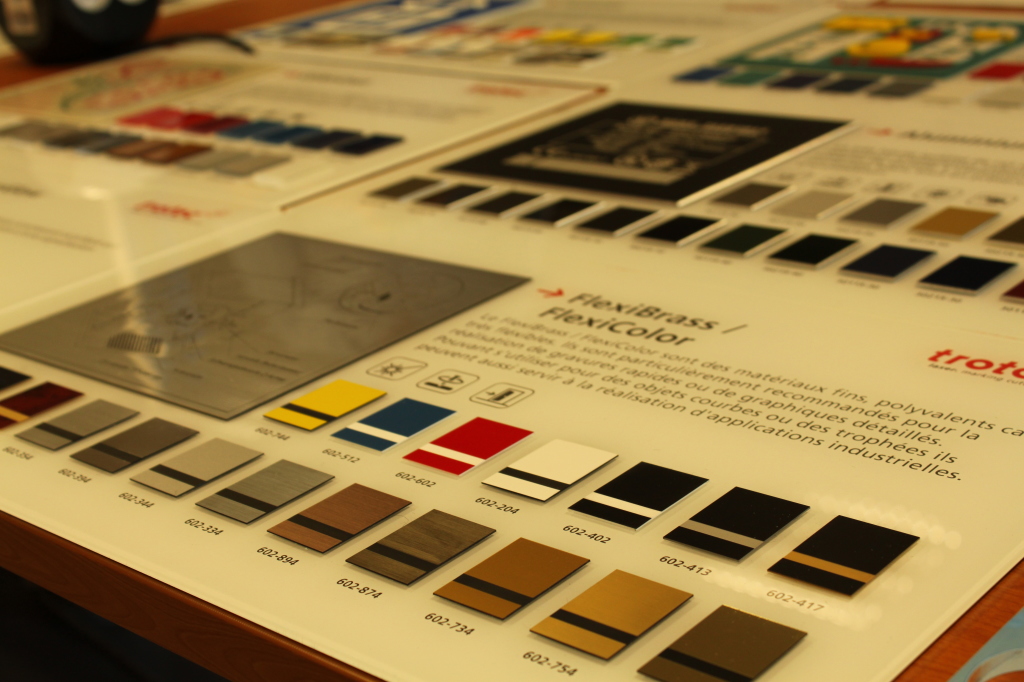

04 Oct Product panel with Trotec laser engraver

What is the mission of Trotec laser in electroluminescent film technology ?

Our mission as laser machine manufacturer is to support our customers in their applications.

Our clients come to us with industrial project that we can respond very easily.

And what makes a huge difference is that we also develop the much more sophisticated applications. Electroluminescent film printing is part of it.

What training you offer helps make a difference with your competitors ?

- Two things:

Team training. Here below the principle we adopted:

"Today, a vendor who enters the team will be trained for two or three months to all applications. Within two or three months, he will bring virtually anything and it will cost us.

By cons, we will invest a lot in him, so that he learns the operation of machinery, and be able to understand the major applications.

When you have the basics of how, practical understanding of machines and applications, then you can explore new things that will bring you customers.

The second major in business logic, or rather technical and commercial development.

Our sales teams are teams that are trained to intervene technically on a machine in the sense that they are able to repair a machine, change a laser tube, to redo the factory settings of the machine ... and that gives a level of credibility with customers, because it says that the person in front of him, is not a seller who is there for him to sign purchase orders and disappears thereafter.

It is the latter which will be followed by the same person. I often tell the sales force: "When you promised the moon to your customers, you'll have to deliver it. "And here, for once, was on the team, a discourse with customers is" The laser is great! We will make full of beautiful things together on your applications, but beware! Here also the limitations of the exercise, so do not try to have something extraordinary. ".

Assistance is an integral part of laser investment, or there's there a subscription?

-There is two things: free consultation. The downstream part is when you sign the contract. At the sale of a machine, we will deliver, we will put it on, we'll install it and we will train people. "Training people" also means to offer our clients "training budget" that is raised with respect to the payroll. Trotec Laser is a training organization approved by the state. So today, a customer wanting to become a distributor of electrolumnescent printing tells us: "I have so many people to trained to the use and operation of this machine" can enter a training program, which in part reimbursed by the governement. Educational content that is linked to the machine is large enough to be considered a professional training.

We will resume in training as:

-the basics of the laser

-the basics of operation and principle:

* What is the cut setting?

* What is burning limit?

* What is tagging?

* Why Co2 only works on a part of applications?

* What is the other types of lasers?

- Do I grant authorization to used Electroluminescent store patents?

What Case of failure of the most common laser? Too sluggish performance? A poorly insulated or poorly conditioned room? What are the issues that may limit these types of damage?

- I have a client who has his laser machine for 12 years. Some customer "kills" after 3 years, but on average it is between 7 and 10 years. The hydrometric has a significant impact on either the process or the laser. We need the laser is in a room around 21/22 degrees. Temperature is important. If the workshop has not been heated, a weekend of winter, and you do your work laser background, it will run shorter than his normal life. Lasers working in workshops heated to 30 degrees, have a shelf life of less than 50%.

Why that's happens? A dilation of the materials?

There are many factors but the temperature is a point to consider.

We say to our customers, during pre-sales, to be vigilant, because this is the life of your machine that is at stake.

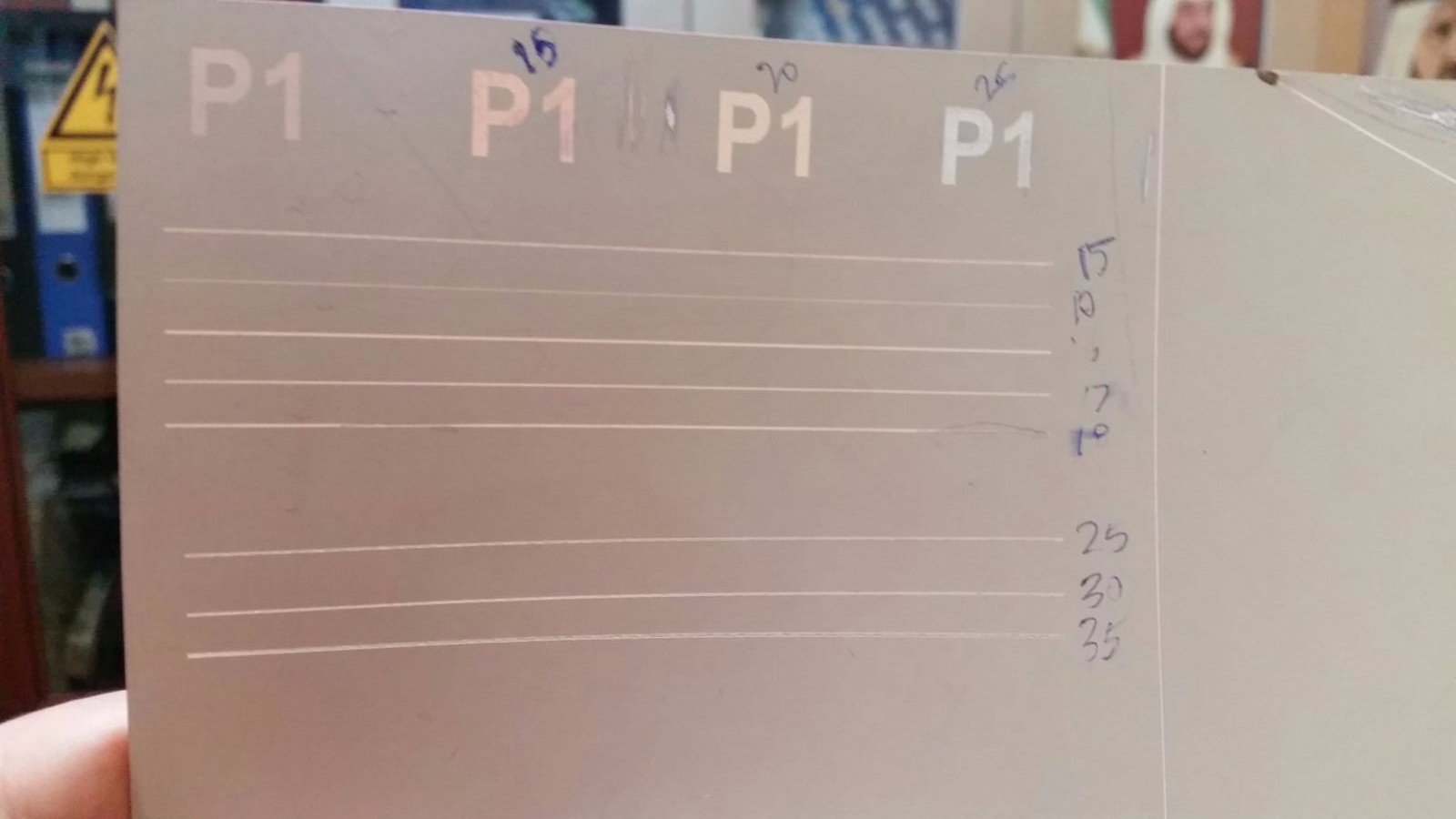

This is often due to misuse. The laser beam has a large diameter which are not convenient if you want to do small works. The radius is going to type in multiple mirrors to get over the material that you want to work. But if it is not focused, nothing will happen. We'll pass through a lens that will focus the beam. Where there is maximum density is called "focal point". If we do not place the focus at the right distance from the material, it will lose its effectiveness. With two millimeters apart, your engraving will not beautiful, or your cut will not be accurate, and people call to tell us that their machine is malfunctioning. The base was taken with them.

We can also do a little careless mistakes: the phone rings and I continue to raise the plateau on which the electroluminescent panel is laid. I do not watch but the plate will hit the arm where are the laser. This can distort the "head" or worse, arm-twisting. When dealing with support calls under the pretext that "not too serious machine," we see the arm that is arc-shaped, it is understood that the employee did not want to tell his boss. It is only a few millimeters, but with the laser, it's huge!

It repairs itself very well, but this can lead to small changes in the machine.

-There Several technical issues:

How an entrepreneur can contact you, whether in the USA, Europe and Asia, in order to get into the industry of electroluminescent? What kind of communication do you have with the public?

-Electroluminescent store website is the entry point to the obvious. It presents our machines, but it also explains what is most appropriate in each case. A print house who needs to increase its production can leave contact information and we freely callback within 24 hours. If in a hurry, there is, on the site, contact information where he can join us from 9am to 18pm. It puts immediately contact a team.

What is the first step in which companies must be prepared to proceed with a leasing rental to aboard volume sales with your laser machines?

- Will try to determine the volume with it, how many pieces will he work a day, a week or a month, no matter the size of machine, we need to determine what will be of your interest . We are specialists in laser, but electroluminescent store is specialized in printing solution.

Buyer must ask the right questions: How do the edges to the heat of the laser? What are the forms that we can do? Is there geometrical limits? Sharp corners are accepted? Can we afford holes in the material? How can they be spaced? Generally, we work with the Technical Department of this new elctroluminescent store in a continuous way.

For new materials never tested before, we offer a laboratory access. We will then test different techniques to see how the material reacts.

How long is this training and what would be the cost of it?

- It has a good grip for our customers. Generally, when you take two days, we will deliver the machine before. The machine is checked before leaving for no nasty surprises on arrival. This is done by 1:30, leaving us the next day to work on the purely application part of the training. Obviously, during these two days, we will keep a general part, but we will also work in parallel on customer applications. We will not only work on ink pads in knowing he will not have utility. We'll spend two minutes on it because you have to explain. However, we will work on cutting the electroluminescent panels. Preferred deepen some significant aspects of the application. We are not consultants applications. There are things that we learn that apart from books. It accompanies the client. It is specified agrement as a telephone assistance, or internet, you can be made. When customers call us for a problem is, in 80% of the problems between computer and laser machine. This is often related to an update of Windows that we forgot to mention, or the IT department has a new anti-virus and did not warn the user. Once it is stabilized, it may not be a problem, unless you have a breakdown. Sometimes the client omits details like "I changed my PC" or "I've upgraded Windows."

Any redundant skills inside your brand?

- Yes, all connected to headquarter in Austria. All country working with the same system: our national crew keep update. We always tried to increase our initial skills and performance. If our customer need to cut 5 cm, I know that we can do it from headquarter.

We need a minimum of 400 watts which corresponds to a machine called SP-15000. We will send the electroluminescent project in Austria, preparing a test protocol with specific criteria because they can cut until 40 mm plexi.

For example, we provide setting for the television news desk on TF1 20h News show.

"When you promised the moon to your customers, you must have to delivery it."

Darko Pecinici, CEO Trotec France

Does your equipment are properly set?

- Yes, it seems to me.

And from the very beginning we work quality of laser cut, not necessarily the speed up. When company need to increase significantly leading time, the Austrian engineering will feed back all data.

They give us immediately the results of tests existing recorded in Germany, Australia and the United States.

You can also consider that the network Trotec / Electroluminescent store is one of the best weapons against the Asian market which offers lasers machine. Each our customer become an authorized production unit rises up by Electroluminescent store.

What you want to say to help entrepreneur who can find laser machine from €70,000 to € 30,000?

- Several things will intervene:

Quality and precision of printing, durability of the laser machine, ability to done different jobs.

We will also talk about software failure, maintenance, repair and ability to restart a machine.

Take a used Redget for example, for a small companies which want to doing marking print, wrapping cut, signs engraving with few volume sale per days.

This is laser machine in a standard configuration cost 13,000 euros, tax-free find on EBay and Ali Baba.During search, clients can find Chinese about €4 000. Then, they say; how is it possible! Same thing, one is a thief!

So what's questions people ask you first?

- Sometimes customer service is contacted by an entrepreneur "

- I hesitate because I tried to figure out the difference of price."

Others say that they buy to try and save money.

And we see them, usually across six months or a year later, for those who are wounded in their pride. Because those parties finally buy a Chinese machine and are disappointed, do not come back to say that we were right. Going back to the Chinese laser machines, they have qualities but we must understand what is being asked.

Explanation take origin in standard mass production of China. Manufacturer have no real problems to build 10 000, 15 000, 100 000 laser machines. They going to get 30, 40 set in exactly the same way.

The adjustment of the particular focal is done with a crank is made once and for all, on all machines!

Trotec take care of each machine one by one by one. We have a philosophy: “we do not mix genres.” That's means we make difference between plant department and customers management.

Our job is to support our client on their implementation part to provide them the machine that will be able to meet their needs today and follow evolving needs. We are not a financial institution and we don't take any fee margin during leasing time - 3 years, 4 years, 5 years.

That is not a part of our job, customers are free to select funding.

All trotec laser machine come with an Electroluminescent store patents license to allow owner for any method of electroluminescent film production.

Our technical team is trained to help our customers with administrative care to find the best solution:

"You can pay equipment through cash flow, bank loan, leasing.. for us it is completely transparent. However, we are not a financial institution so we do not have the right to create a direct leasing."

Thus, you do not marge on additional fees after sale ?

-No, we do not make money with leasing equipment.

Maybe in 10 years we will create a financial subsidiary. But currently, funding agency are knowledge. Any charged are clearly announced for a 5 years amortized prediction. Thus, accounter can analyzed immediately their investment.

COMPANY SNAPSHOT

Founded since 1997 in Austria Marchtrenk – Trodat

Headquarters in France Ozoir la ferrière

1150 employee(s)

€ 154 million

Francis

Posted at 15:33h, 06 DecemberWe need to produce from 100 pieces per day : do I need to buy 3 or 4 lasers or 1 is enough for this capacity ?